Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

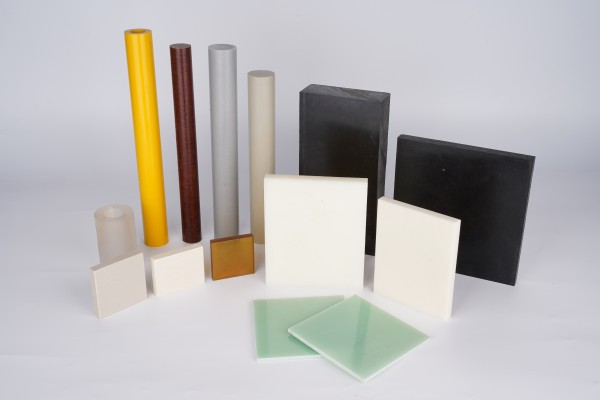

Polasetiki ke e hlonepha haholo joaloka thepa e tala, ka semelo sa polymerigation sa metsoako ea polymer (matrifelecules, e leng libricants, libricants, libricants, li-asterizers, libricants, mmala le litlatsetso tse ling.

Karolo e ka sehloohong ea polasetiki e ratiloe. Resin ke komporo ea polymer e e-so tsoa tsoakoa le lisebelisoa tse fapaneng. Qalong ea Resin e bitsoa lebitso le boletsoeng qalong ka mor'a ho bolokoa ke limela le liphoofolo tse kang lijalo le sebokoleng. Likarolo tsa Resin tse ka bang 40% ho isa ho 100% ea boima ba polasetiki ea polasetiki. Melemo ea mantlha ea polasetiki e khethoa habonolo ke mofuta oa sebaka, empa litlatsetso li boetse li bapala karolo ea bohlokoa. Lijana tse ling ha e le hantle ke tse ling tse lumelloang ke li-syenthetic tse nang le litlatsetso tsa maiketsetso, tse nang le litlatsetso tse 'maloa, tse kang Plexiglass, joalo-joalo

Polasetiki ke tsebo ea likarolo tsa mantlha, ka mocheso o itseng le khatello e itseng bo boholo bo entsoeng ka sebopeho se itseng, 'me mocheso oa kamore o khona ho boloka thepa e matla ea polymer. Polasetiki e bobebe ebile e le matla. Boholo ba Tonakholo ea 0,9-2.3g / MM3 ho tšoha ho monya le ts'ebetso ea molumo o mongobo. Plasttic ho latela tšebetso ea mocheso o holimo e arotsoe molemong oa litšana o tla ba polasetiki ea thempere.

Litšobotsi tsa polasetiki: Ka mocheso o itseng ka mor'a nako ea ho futhumatsa, khatello kapa ho thatafatsa sebopeho sa lik'hemik'hale, ha se sa nolofalle ka mor'a ho futhumatsa, joalo ka ho futhumatsa, joalo ka Mocheso o phahame haholo haholo. Joalo ka polasetiki ea Phenolic (e tsejoang ka hore ke Bakelite), ePOXY Plastics - joalo ka joalo.

Litšobotsi tsa thermoplast: Liphetoho tsa mocheso Lefapheng la ho Bolo-Bang. Sebopeho sa limolek'hule sa polasetiki ha se fetoha. Ha polasetiki ea polyeenene e joalo ka polyeylene polasetiki.

| Karolelano ea polasetiki | Mohopolo | Polasetiki | |

| Classified ka kopo | Polami ea Boenjiniere | Ka kakaretso e bua ka lipolanete tse 'maloa tsa boleng ba indasteri joalo ka tse sebelisoang ho etsa likarolo tsa mochini kapa meaho ea boenjiniere | Pa pc pom ab ab ppo pbt |

| Kakaretso ea Morero | Lisebelisoa tsa polasetiki tse nang le litšobotsi tse akaretsang tsa lisebelisoa tsa polasetiki 'me li ke ke tsa nkela thepa ea polasetiki ea polasetiki | Pvc PS Pnolic, Plastiki ea Amono | |

| TLHOKOMELISO E KA SEBELISANG LE 'mele le lik'hemik'hale | Thermoplane | Polasetiki e ka futhumatsang khafetsa ho nolofatsa le ho pholile ho thata ebile e bopiloe | Pa pc pom abs ab ppo pbt pvc ps |

| Plasmostosting | Polasetiki e phekotsoeng ke mocheso ebe e nolofatsa mocheso le ho bopuoa hape. Litšoantšo tsa synthetic tse ka sebelisoang hang | Phenolic, amino, epoxy le resin | |

| Sebopeho sa polasetiki | Bolulo, li-chillers, li-colours, li-coloranis, li-matlabilizer, lubricants, jj. | ||

| Mabaka a amang boleng ba likarolo tsa polasetiki | 1.Product moralo oa bo-ralpintic | ||

| Parametezation | Mocheso | a. Mocheso oa "cylinder Mocheso oa nozzle c. Mofuthu oa Mold | |

| Khatello ea khatello ea maikutlo | a. Hlobola khatello ea m. Injection khatello c. Ho ts'oara khatello ea d. Khatello ea morao | ||

| Lebelo | a. Screw lebelo b. Mold Closing Speed C. Lebelo la ente d. Lebelo la ho bula Hloka | ||

| Nako | Nako ea ente B Ho ts'oara nako C ho pholile | ||

| Lintho tse amang lipalesa tsa thepa ea polasetiki | 1. Mefuta ea polasetiki 2. Mokhahlelo oa Mold |

Litšireletso tse ka sehloohong tsa lihlahisoa tsa polasetiki:

1. PHIAK : Ka lebaka la litekanyetso tsa ente kapa ka mold ho latela litaelo tsa polasetiki ea polasetiki, haholo ka har'a mold

2. Shrinkage: Ha polasetiki e qhibiliha karolong e tšesaane haholo, ho thata haholo ho boloka khatello e ngata ea ho tlatsa lesika le tšoloha le ho thehwa ha likopano

3. Fusion Line (mohala oa metsi)

4. Lenaneo la ho phalla ka har'a mmala o fokang ka holim'a metsi e le setsi sa metsero e potolohileng selemo

5. Ho haella ka sekhomaretsi (tlasa khatello ea maikutlo

6. O ka holimo (Convexx

7. Bubble: ka lebaka la lisebelisoa tse tala ka ho omella ka botlalo, metsi ka mocheso o phahameng oa China le lebota la sehlahisoa se hole le bokaholimo ba Sehlahisoa. ea sekhahla se futhumetseng ho feta karolo e potlakileng ka ho futhumala, bohareng ba koluoa ea polokelo ea phomolo, e le hore karolo e bohareng ea likotlo tse sa lekaneng tsa phomolo tse hlahisitsoeng

8. Scorching: Ka lebaka la mabaka a ho phatloha a ho fifala le ho fifala

9. Deformation: Sehlahisoa se thetsoang ka lebaka la khatello ea maikutlo ea kahare kamora ho holisa defformation ea ho ba teng

10. Maqhubu a marang-rang

11. Lihlahisoa tse tšoeu: Lihlahisoa tse bopehang li tima hlobo e kholo ea ho itlosa bolutu ka matla

12. palesa ea lintho tse bonahalang: Ka lebaka la lisebelisoa tse tala ka ho omella ka botlalo, le ho thehwa ha matheba kapa mela ea lipaterone

13. Phapang ea mebala: bokaholimo ba sehlahisoa ha bo lumellane le 'mala o tloaelehileng oa sampole

October 15, 2024

October 20, 2022

October 20, 2022

February 10, 2023

E-mail ho mofani oa sena

October 15, 2024

October 20, 2022

October 20, 2022

February 10, 2023

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.