Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Pei (polyotherimide)

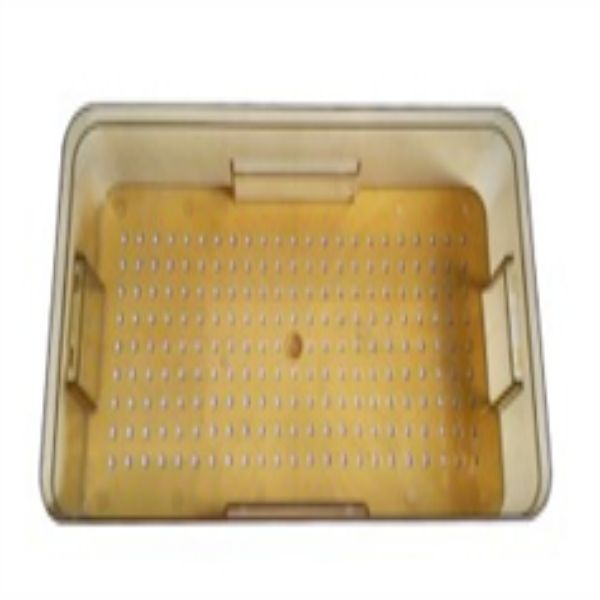

Sehlahisoa se akaretsang sa sehlahisoa sa sehlahisoa sa lihlahisoa tsa tlhatlhobo ea lihlahisoa tsa tšebetso

Pei polytdimide ke bosholu ba bong bo khethehileng ba amorpicer, lebitso la Senyesemane: Polyetdimide, e khutsisoa e le Pei. Sebopeho sa eona sa lisele se na le sehlopha sa mexico se sebetsang hantle le sebopeho sa batho ba nang le maqhubu, ha ho bapisoa le li-polyimide tse ling tsa aryl. Ntle le moo, Pei a ka ntlafala ho feta ka ho eketsoa ha fiber ea Glass. Ntle le moo, Pei e ka fetoloa ka ho eketsa fiber ea khale ho ntlafatsa ts'ebetso ea eona.

01 PROI Product Inbertview

Pei ke polyotherhimide (Pei). Pei ke polyphous ea Amorphous ka mocheso oa khalase oa ho fihlela 215 ° C. E na le thepa ea bohlokoa e tšoanang le ea peek, hammoho le moferefere, le makhapetla le malakabe-bolutu-re. E ka sebelisoa libakeng tse phahameng tsa khatello ea maikutlo ka khatello e phahameng ea khatello ea maikutlo kapa khatello ea maikutlo, likarolo tsa motlakase tsa moea, litsamaiso tsa motlakase .

02 Litlhahlobo tsa sehlahisoa sa Pei

Matla a phahameng a mabotho a phahameng, matla a kaholimo ho 110mpa

Matla a phahameng haholo, matla a 150mpa kapa ho feta

Bophahamo ba thermo-mokhoa o nang le mehato e nepahetseng, mocheso o futhumetseng ho feta kapa o lekanang le 200 ℃.

Ho hanela ho hanyetsa le ho hanyetsa ts'ebetso ea mokhathala

Thepa e Ntle ea Ntoa ea Loate e Ntle, Mefuta e tlase ea mosi

Mefuta e metle ea lefu la lipono

Bokhoni bo boholo bo lekaneng ba ho tsitsa, ba sa sebetseng hantle ba keketseho ea mahlo

Ho hanyetsa mocheso o phahameng oa mocheso, ho ka sebelisoa tlasa 170 ℃ ka nako e telele

Phetiso ea li-microwaves

Ts'ebetso e qaqileng

01 Ho supa litšobotsi:

Plasetiki ea translucent Amber Seriti, fetotsoe ka likhoele tsa khalase ho ba mohloaare ka 'mala.

02Machanity Properment:

Matla a phahameng a mashome a mane a mashome a mane, matla a phahameng a ho qhalana, a matlafalitsoe ke polasetiki e phahameng haholo ho feta bongoana se seng se sebetsang se phahameng haholo.

03Eorftrity Theitrity:

Matlafatso e ntle ea motlakase, matla a mangata a phahameng, a hanyetsanang le arc joalo joalo.

04 Khalefo ea lithethefatsi:

Ho fapana le polasetiki e meng ea anicalphous, Pei e bontša ho hanyetsa e fapanyetsang ho hanyetsa hangata ho lik'hemik'hale tse fapaneng. Ha ho angoe ke li-hydrocarbons tse ngata ebile li hanyetsoa ke lijalo ka atibriccic aticacic, tharollo ea letsoai, le basse ea methapo (ph <9). Le hoja e qhibiliha ho hateloa ha hydrocarboard e kang Trichloromethane

05 Thepa ea Redame Redamentant:

Pei ke mosi oa chelete e tlase le mosi ; Palo ea mosi o behiloeng ke mokhoa oa nbs o 0,7 (palo ea mosi ka mor'a 4min (palo ea mosi ka mor'a 20min) ka ho latellana.

Ts'ebetso ea ts'ebetso ea 06:

Ts'ebetso e ntle ea ts'ebetso, e ka etsa hore lihlahisoa tse rarahaneng tse nang le mokhoa o mongata, shrunkage ea mehala e nyane, le liseketso tse tlase tsa tšepe li haufi le tšepe, li kenella . Ka hona, e sebelisoa haholo molemong oa lihlahisoa tsa ho fana.

07 radiation radiation:

Ho hanyetsa hamonate haholo ho nosetso ea Ultraviot, ha ho se na maemo afe kapa afe a tsitsitseng, a ka khona ho pepesetsoa tlhahlobo ea Xeon lam ea Tenson lammile e nyane;

Pei o boetse o bonts'a khanyetso e ntle ea radiation ea γ - ka har'a sobat ea 60 ho isa ho 1m ka hora ea 5M ka mor'a matla a matla a 6%;

Pei e ka kenella ka microwave le ho ikhathatsa.

08 e bohlasoa:

Ho hlekefetsoa haholo ho ngangisana, leha e le mochesong o phahameng le hona ho na le khatello e phahameng haholo.

03 Litšireletso tsa indasteri ea Pei

01ehectrical le elektroniki

Matla a motlakase a pepere a Pei, sekoti se ka bokhabane mochesong o phahameng, 'me lintho tse ling tsa motlakase li feta boitsebiso bo fapaneng ho etsa hore boitsebiso bo ratoang bakeng sa iphoro ea motlakase le ba elektroniki. Joalo ka tlhahiso ea lithibelo tsa lefutso, mekhoa ea potoloho, lithutsoana tsa potoloho, li-coambers tse hatisitsoeng, likahare tsa potoloho, liilaketions.

02mechani Indasteri

Indastering ea mechine, matla a phahameng a Pei, a thata, a hanyetsa haholo le a hanyetsa likhara, lipekere le indastering ea mechine.

Indasteri ea 03dical

Likhoeng tsa bongaka, ho thatafalloa ho thatafatsa Pei, litšupiso tse phahameng tsa mocheso le lits'oants'o tsa tlhaho tse ka bang 130 ° C) li sebelisoa ho likokoana-hloko tsa bongaka tsa bongaka tsa bongaka.

Indasteri ea 04food

Indastering ea lijo, Pei hase chefo e nang le chefo, mocheso o phahameng o sa sebetseng, o ka sebelisoa lithong tsa mechini ea US indasteri, ho amoheloa sehlahisoa, Microwave ovens, hateware le joalo.

05transportiation

Indastering ea lipalangoang, matla a lipalangoang Pei le ho hanyetsa, ho khutla ha mocheso, ho khutlisoa ka matla. , hatch sekoaelo, racks tsa mekotla, makhopho a setulo, le litafole tsa lijo, jj.; Carbon Fiber e matlafalitsoeng ea Pei e sebelisoang bakeng sa li-helikopthara tse ncha; Pei foam e sebelisoa e le lisebelisoa tsa ho hlakoloa le tsa boits'oaro tsa marang-rang bakeng sa lifofane; Pei e boetse e sebelisoa bakeng sa likarolo tsa enjine ea likoloi, litulo tsa mocheso tse phahameng, li-sensory tsa motlakase, li-sensors tsa moea, li-mossous tse sebetsang tsa moea.

Tšimo ea 5G: Sesebelisoa sa Khokahano sa PUSELETSO (Informared Transidence), lik'hamphani tsa RF, li-find

Indastering ea liaparo, Pei le eena o etsoa ka li-tabers bakeng sa liaparo tse sirelletsang bakeng sa li-mollo tsa mollo le bakhanni ba lipetlele. NOPIN Woolen Bong le Limilema le Liphoofolo tse ling li phutholoha li-charns, masela le tšireletso ea litlolo tsa mahala tsa uv.

05 Pei Re Tunteft

Pei gf30 ke polyETIMID (Pei) profil profil ka 30% e khuts'oane ea khalase ea khalase. Ha ho bapisoa le Pei ea sa ea laheng, sehlahisoa sena se fana ka matla le mosimuse, ho hanyetsa hamolemo ho hama ka mokhoa o kotsi, le ho holofatsa ka tlase ho hola.

Sehlahisoa sena se ka sebelisoa libakeng tse phahameng tsa khatello ea maikutlo ka khatello e phahameng, khatello ea maikutlo, likarolo tsa motlakase, lisebelisoa tsa motlakase tsa moea, le Sistime ea Motlakase.

Jtypei® GF30 GRANS Fiber e matlafalitsoeng ea Pei

Matla a futhumetseng a phahameng haholo, ka matla a 160 mpa kapa ho feta;

Matla a mangata a lebohang, matla a kaholimo 210mpa;

Matla a matle a ho be le thermo - mocheso oa futhumatsang o moholo ho feta kapa o lekana le 210 ° C;

Thepa e metle haholo ea ho phomola lelaba la ntoa ea leholimo, Arc

Mokhoa o motle oa puo le thepa ea hau;

Boholo bo tsitsitseng bo tsitsitseng bo tsitsitseng, bo lekaneng ba keketsetso ea khatello;

Ho hanyetsa mocheso o phahameng oa mocheso, ho ka sebelisoa nako e telele ka 170 ℃.

October 15, 2024

October 20, 2022

October 20, 2022

February 10, 2023

E-mail ho mofani oa sena

October 15, 2024

October 20, 2022

October 20, 2022

February 10, 2023

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.

Tlatsa tlhaiso-leseling e eketsehileng e le hore e ka ikopanya le uena kapele

Polelo ea boinotšing: Lekunutu la hau le bohlokoa haholo ho rona. Khamphani ea rona e tšepisa hore ha e etse hore u se ke ua senola tlhahisoleseling ea hau ho ea pele.